H2P Series Pump/Fan Drives

Ratings from 220 - 600V up to 800HP

Pump and Fan applications

The Benshaw H2P Series sets the new standard for variable frequency drives for pump and fan applications. It includes application software designed to perform many functions including advanced PID functions, multiple pump or multistage pump control, lead lag, simplex, duplex, triplex, multiplex with the capacity of multiplexing up to 8 drives. Cost saving result by reducing PLC’s and peripherals typically required to achieve these functions that are now integral to the drive... The results are reduced maintenance cost, better system control, and improved pump and pipe monitoring and protection. If you have one or multiple motors/pumps in a system that require constant pressure or flow, then this is the drive for you.

Benshaw H2 Pump™ Series Drives comply with key industry standards (UL/cUL/CE), offer built-in EMC filters (standard in all 480V models), standard RS-485 Modbus/RTU/BACnet/Metasys-N2 communication cards and a full range of programmable features.

Highlights

Flux braking enhancing deceleration performance in V/F mode

Standard Features

Hardware

- 240V: 7.5HP~25HP (ND), 5HP~20HP (HD)

- 480V: 7.5HP~800HP (ND), 5HP~600HP (HD)

- Protected Chassis IP20, 7.5~300HP / Open Chassis IP00, 400~800HP UL Enclosed Type 1 with optional conduit box (7.5HP~800HP)

- LCD Display/Keypad

- EMC Filter Compliant Category C3 (480V, 7.5HP-800HP)

- Single Phase Input (derating required)

- Plenum Rated (conduit option required)

- Built in DC Reactor (480V, 50HP~800HP)

Communications

- Standard: RS-485 Modbus - RTU, BACnet, Metasys-N2

- Options: Ethernet/IP, Modbus - TCP, Lonworks

Software

- PID Control with Sleep Mode and Wake Up Boost, Broken Pipe and Under Load Detection

- Multi Motor Control – One drive to control the starting and stopping of up to 5 auxiliary motors up to 8 with option card

- Multiplex mode, Simplex, duplex, triplex up to 8 motors

- Master-follower

- Multiplex via RS-485

- Lead/Lag load share

- Pre-Fill and Soft-Fill

- Fire Mode Input

- Start and End Ramp – settings for quicker accel/decel times when below minimum speeds

- Decel Valve Ramp – Separate decel ramp frequency and time settings when stopping

- Time Event Scheduling – Program run times for 7 days operation

- Flow Compensation – Compensate for losses in long pipe lengths

- Backspin Timer

- Pump Clean Operation

- Load Tuning

- Drive Output Level Detection – Set warning/trip limits (current, power, others) to detect drive operation beyond limits

- Oil Pump Starter Control

- Damper Control and Monitoring

- Broken Pipe Detection

- Under Load Detection

- Pre-Heat Function (Condensation Control)

Programming

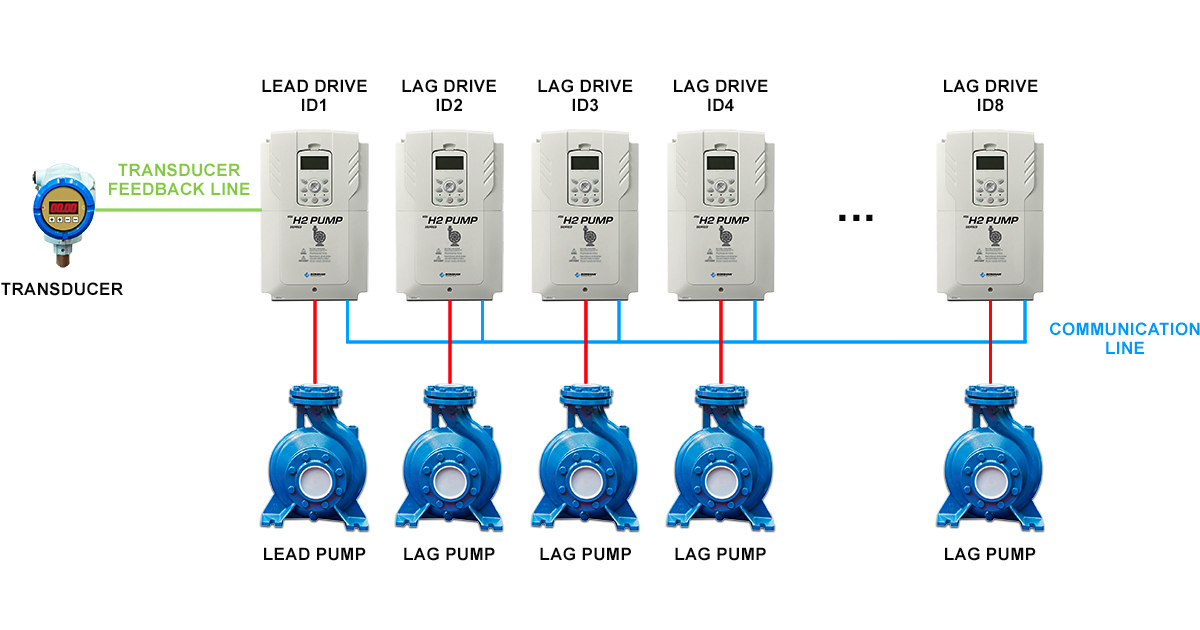

Lead Lag Operation

Multi Stage Pump Control

This mode is also referred to as “Master-Follower” or Lead-Lag/ with Alternating option“. The system can be configured without using a controller (such as a PLC) by connecting the drives via communications. Wiring is minimized with the use of Modbus-RTU communications, which eliminates the need for additional options. Running order and alterations are based upon operation time. If a failure occurs to the master drive, the next drive will run as the master.

Features:

- Pumps are individually connected to AC drives, and a master drive controls the entire system

- Pumps are controlled by the unique PID function of the AC drives, so external devices such as PLCs or contactors are not required

- The speed of each pump is controlled by individual AC drives to save energy

- Since the operating time of each pump can be evenly distributed, the life expectancy of the pumping equipment is extended, reducing the total system operating cost

- If the master AC drive malfunctions, the next AC drive takes over as the master, and continuously controls the system without failure