This section of the Benshaw website features helpful insights from the motor control experts at Benshaw.

Read on to learn how our applied motor controls can be used to improve performance and reliability.

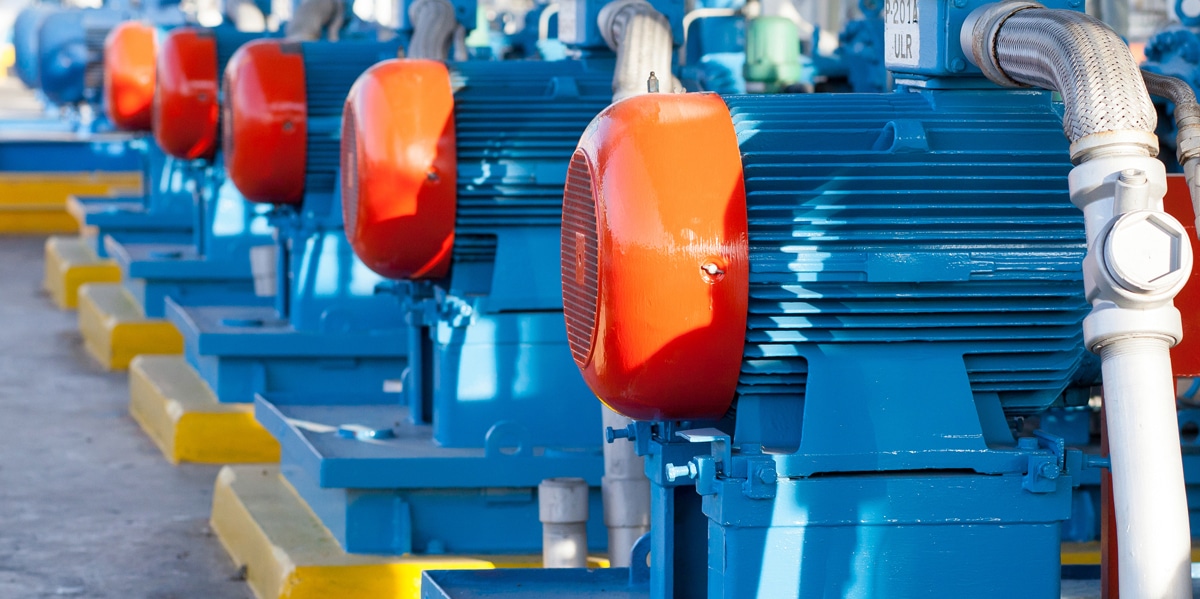

Motor Control in Pumping Applications

/in Motor Control Insights /by Platform ManagerMotor control in pumping applications is often mission critical. These pumping applications span a wide range of industries, from agriculture (crop irrigation) to wastewater treatment, oil and gas production and many others where fluid transfer is required. Given the critical nature of these applications, process disruptions due to pump system failure can quickly become a major issue.

Benshaw 2.0

/in Motor Control Insights /by Platform ManagerBenshaw 2.0 is a wide ranging initiative to identify and address major issues that can help our customers in their efforts to thrive and succeed in an ever more challenging global marketplace.

Get Your Motor Running

/in Motor Control Insights /by Platform ManagerWe get lots of questions every year about applying motor controls. Most of these questions are related to selecting the right starting method, based on the customer’s particular application. To address these questions, Benshaw has released a new three-part series of white papers that provides valuable technical information intended to help customers “Get their motor running.” These white papers explore the dynamics between motor design, starting current requirements and the various starting methods used to maximize performance and improve energy efficiency in fixed speed applications.

Selecting a Soft Starter Model: Where Do I Start?

/in Motor Control Insights, Other /by Platform ManagerThere are several steps involved in selecting a soft starter model most appropriate for your installation. Bypass type, the motor connection method, start duty and operating conditions must all be considered. A new eBook from Benshaw can help guide the way.

Benshaw, Inc.

615 Alpha Drive

Pittsburgh, PA 15238

United States

Benshaw Canada Controls, Inc.

550 Bright Street East

Listowel, Ontario N4W 3W3

Canada